Krusty Kitchen

Project Overview:

Designed for Carnegie Mellon’s 2012 Spring Carnival, Krusty Kitchen is a Spongebob-inspired tangible interaction game in which players follow onscreen recipes by assembling wooden blocks resembling deep-sea ingredients. This two-story wooden structure designed and built by students brings the zany-ness of Spongebob to life!

Design Overview:

Working inside of an existing design style and the wider context of the Spongebob universe presents an opportunity to work in a vibrant and exciting color palette that evokes strong associations with the television show. As booths are frequented by area families (especially those with children), the booth game needs to be accessible to children as young as five.

For 2012, we chose to place our game into the kitchen of the Krusty Krab, the restaurant where Spongebob works. We wanted to work the game into the natural flow of the booth, so we decided to put visitors into the role of a fry cook in the Krusty Krab. Players will be able to fit together interlocking, electronically augmented blocks to recreate deep-sea recipes. From sea-horse radish to jellyfish jelly, visitors will combine a wide array of fanciful ingredients in an engaging interactive experience that ties together themes and references from across the Spongebob universe.

Each block has inlaid wiring and resistors that feeds back to a sensor placed into stove burner. By summing the resistance and doing some simple circuit mathematics, a computer can easily tell which blocks are in a given assembly. To get ingredients in the correct order, parts interlock through a series of protrusions and insets that make it impossible for incorrect parts to fit together. Because the insets are on the bottom of each piece, Krusty Kitchen forces users to turn over each piece and really get into the tactile experience of assembling the food.

Process Work and Workflow

Jason and I began by doing line drawings to play with how various parts would fit together. Then, I cut small blocks of foam and sanded/cut them to the desired shape:

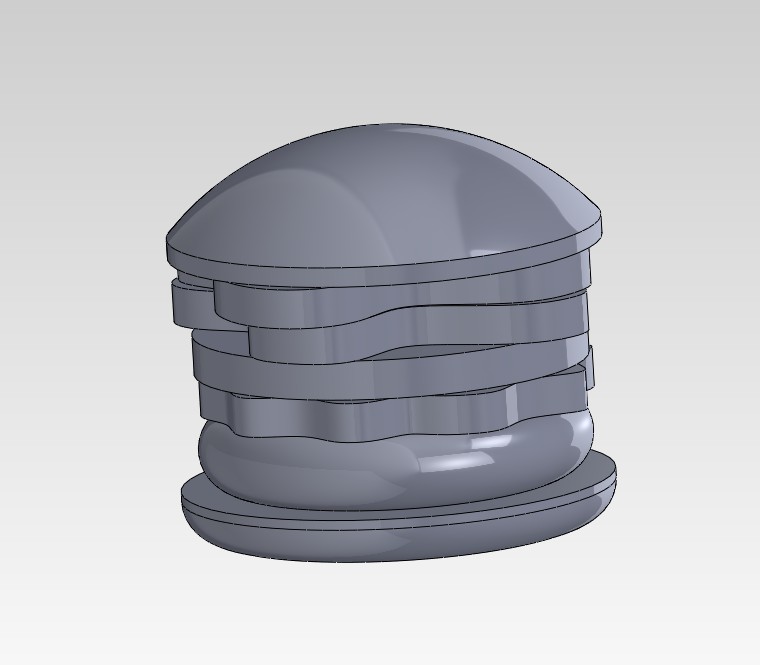

After developing an initial form, we modeled each of the parts in Solidworks, taking care to size things appropriately and ensure pieces fit together properly. The picture below is all of the Solidworks parts stacked on eachother.

Following that, we imported the Solidworks models into rhino. Our CNC tech then split the models so that that we could cut the insets into one half and the rest of the part on the other half. He then created toolpaths for a CNC router to mill them all as exactly as possible. Once we were able to get time, we used the CNC router to mill 3 of each game piece.

Then, using copper tape, wire, and solder, I made a model of each part’s electronics. Each side of the part has copper tape contact strips, then a small hole drilled through the piece either runs a wire to the opposite side or holds a resistor that will connect the two. Each physical part has a a resistor and a no resistor variant, allowing for more parts than types of resistors the software has to be able to differentiate. After making a model of each piece and testing connection, I handed them off for assembly.

Gameplay and Installation

One of the key parts of Krusty Kitchen was marrying the onscreen graphics to both the physical forms and to the feel of Spongebob as source material. To that end, we kept in-game graphics fairly simple, using vector based off of the CAD designs of our exterior structure. For loading, intro, and exit screens, we dipped into vector art based off of the Booth’s architecture, as well as the rich color palette of Spongebob.

Start Screen:

The game was then installed into our booth into a mock stove. Game pieces were stored in two deep fryer baskets set into the middle of the stove, easy to access for either player.

Collaborators: There were around 70 people who helped in some way with the Booth and therefore the experience of the game. The following section lists more specific roles. Booth is an incredibly large undertaking, so often tasks are accomplished by making a model part or component of which others make copies. I’d like to thank everyone who was involved in this project and kept me sane, especially our Booth Chairs Kunal Deodhar and Junki Nakayama.

Concept and Experience Design: Thomas Doyle, Jason Paul

Part Design: Jason Paul, William Maher

Part Manufacture: Kevin Kuntz, Winston Avil

Electronics Manufacture: Jake Flittner, Robbie Murcek

Game Housing Design: Bryan Bleda, Jason Paul

Game Programming:Andy Biar

Game Art: Kapil Easwar

Sound Design: Andy Biar